-

Maszyna do pakowania torebek

-

Maszyna do pakowania granulatu

-

Maszyna do pakowania płynów

-

Maszyna do pakowania w proszku

-

Mini maszyna pakująca Doypack

-

Maszyna do pakowania torebek z herbatą

-

Maszyna do pakowania kawy

-

pionowa maszyna pakująca

-

Maszyna do pakowania przepływowego

-

Maszyna do pakowania w torebki stojące

-

Obrotowa maszyna do pakowania próżniowego

-

Maszyna do napełniania

-

Pozioma maszyna do pakowania Doypack

-

Gotowa torba

-

Akcesoria do maszyn pakujących

-

maszyny do wypełniania i pokrywania

Maszyna do pakowania mieszanego żelu

| Miejsce pochodzenia | Guangdong, Chiny |

|---|---|

| Nazwa handlowa | ZCHONE PACK |

| Orzecznictwo | ISO,CE |

| Numer modelu | ZC-8200 |

| Minimalne zamówienie | 1SET |

| Cena | $18,000~$24,900 |

| Szczegóły pakowania | Standardowe drewniane opakowanie eksportowe |

| Czas dostawy | 15 |

| Zasady płatności | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Możliwość Supply | 1/zestawy/15dzień |

| Nazwa produktu | Maszyna do pakowania dziobków | Miejsce pochodzenia | Foshan Chiny |

|---|---|---|---|

| Aplikacja | Napój, płyn i sok | Materiał opakowaniowy | Plastikowy |

| Woltaż | 220 V 380 V 50/60 Hz | Kluczowe punkty sprzedaży | Automatyczny |

| Podkreślić | Maszyna do pakowania mieszanego żelu,Maszyna do pakowania plastikowego mieszanego żelu,Sprzęt do pasty żelowej 220V |

||

| Rodzaj maszyny do pakowania | |

|---|---|

| Maszyna do pakowania granul | |

| Maszyna do pakowania płynów | |

| Maszyna do pakowania proszku | |

| Maszyna do pakowania z saków stojących | |

| Maszyna do pakowania pionowego | |

| Maszyna do pakowania poziomego | |

| Maszyna do torebek do herbaty | |

| Maszyna do pakowania ziaren kawy | |

| Maszyna do pakowania poziomego |

Maszyna do pakowania żelu mieszanych materiałów płynnych, sprzęt do pakowania pasty żelowej do reakcji chemicznych w saszetkach

Maszyna do pakowania plastrów żelowych z mieszanymi płynami to zautomatyzowane urządzenie specjalnie przeznaczone do pakowania substancji płynnych, żelowych lub półpłynnych. Jest szeroko stosowana w medycynie (takiej jak plastry przeciwgorączkowe, plastry), kosmetyce (takie jak maseczki do twarzy, płatki pod oczy), produktach zdrowotnych i innych dziedzinach.

1. Główne funkcje urządzenia

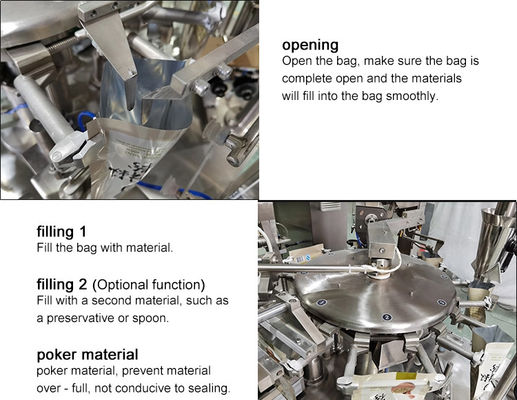

Precyzyjne napełnianie: Może precyzyjnie dozować płyn lub żel z dużą dokładnością (zazwyczaj z błędem ±1%).

Formowanie uszczelniające: Plaster jest uszczelniany za pomocą technologii prasowania na gorąco, ultradźwięków lub uszczelniania na zimno, aby zapobiec wyciekom.

Cięcie i pakowanie: Automatycznie tnie do wymaganego kształtu (okrągły, kwadratowy itp.) i uzupełnia pakowanie pojedynczych sztuk.

Dodatkowe funkcje: Niektóre urządzenia obsługują kolejne procesy, takie jak etykietowanie, kodowanie i pakowanie w pudełka.

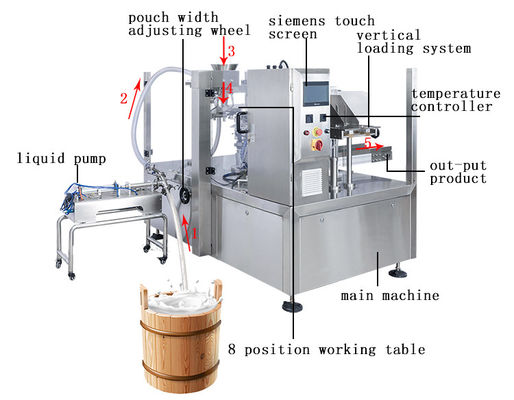

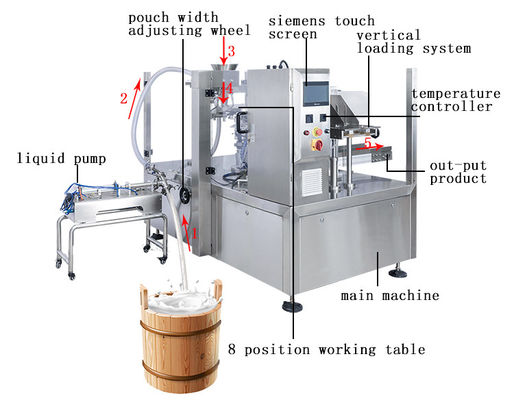

2. Kompozycja struktury rdzenia

System podawania: Przechowuje i transportuje surowce płynne/żelowe i może być wyposażony w mieszadło zapobiegające wytrącaniu się.

Głowica napełniająca: Precyzyjna pompa (taka jak pompa perystaltyczna, pompa zębata) kontroluje objętość napełniania.

3. Część formująca:

Odwijanie podłoża: Uwalnia warstwę nośną (włóknina, folia itp.).

Powlekanie żelem: równomiernie pokrywa płyn na podłożu.

Uszczelnianie folią: zakrywa folię ochronną i uszczelnia zgrzewem.

Moduł cięcia: wykrawanie lub cięcie laserowe w celu zapewnienia równych krawędzi.

System sterowania: Obsługa PLC lub ekranu dotykowego, regulowane parametry (temperatura, prędkość, objętość napełniania itp.).

4. Cechy techniczne

Konstrukcja higieniczna: część stykająca się jest wykonana ze stali nierdzewnej 316 lub materiału spożywczego, który spełnia normy GMP.

Szeroka adaptacja: może obsługiwać ciecze o różnej lepkości (takie jak żel na bazie wody, silikon).

Konstrukcja antyoksydacyjna: niektóre urządzenia są wyposażone w ochronę azotową, aby zapobiec pogorszeniu się żelu.

5. Środki ostrożności przy zakupie

Charakterystyka materiału: lepkość, korozyjność, obecność cząstek itp.

Wymagania dotyczące wydajności: wybierz modele półautomatyczne lub w pełni automatyczne w zależności od produkcji.

Zgodność: musi być zgodna ze standardami branżowymi (np. leki muszą spełniać certyfikaty FDA i CE).

Skalowalność: czy obsługiwać kolejne aktualizacje funkcji (takie jak kontrola wizualna).

Specyfikacja maszyny:

| Pozycja | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Pakowanieprędkość | MAKSYMALNIE 60 worków/min, w zależności od jakości folii opakowaniowej, materiałów opakowaniowych, wagi opakowania itp. | ||

| Rozmiar worka | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Typ worka | Worki gotowe, worek stojący, worek czterostronnie zgrzewany, worek trójstronnie zgrzewany, worek o specjalnym kształcie | ||

| Zakres ważenia | 10g-1kg | 10g-2kg | 10g-3kg |

|

Pomiar dokładność |

*≤±0,5~1%, w zależności od sprzętu pomiarowego i materiałów. | ||

| Maksymalna szerokość worka | 200mm | 250mm | 300mm |

| Zużycie gazu | 0,8Mpa 0,3m3/min (Dostarczane przez użytkownika) | ||

| Całkowita moc/napięcie | 2,5KW 380V 50/60Hz | 2,5KW 380V 50/60Hz | 3,7KW 380V 50/60Hz |

| Sprężarka powietrza | Nie mniej niż 1CBM | ||

| Wymiar | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Waga maszyny | 1300kg | 1400kg | 1500kg |

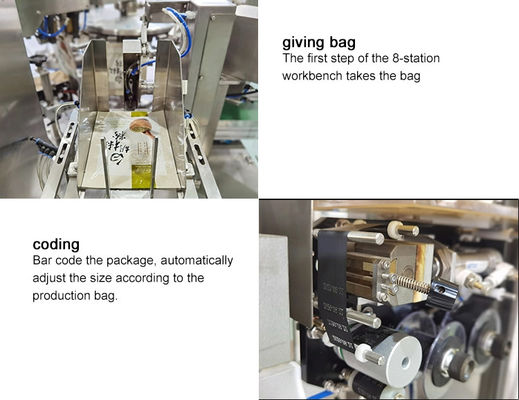

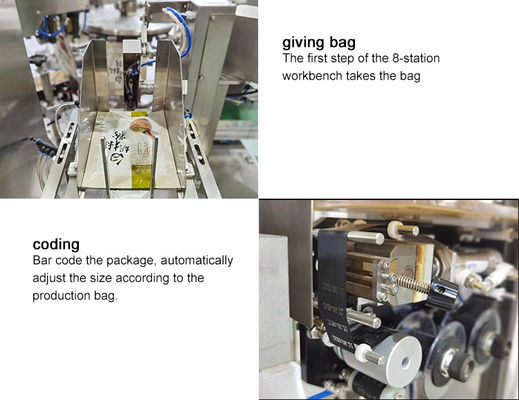

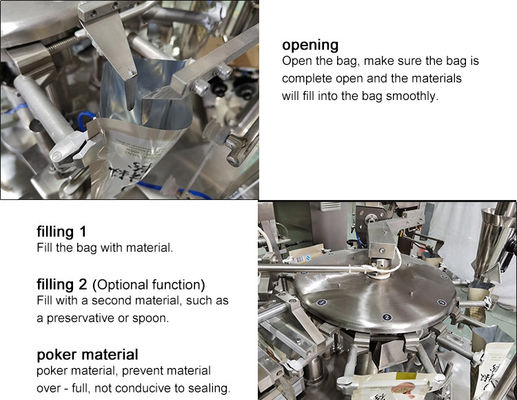

| Przepływ pracy | Podawanie worka→Kodowanie→Otwieranie worka (lub otwieranie worka z zamkiem błyskawicznym)→Napełnianie→Pomocnicze→Wydech→Zgrzewanie→Formowanie i wydawanie produktów. | ||

(Możemy zapewnić Państwu ekskluzywne usługi dostosowywania maszyn pakujących do Państwa potrzeb! Oczywiście, w razie potrzeby możemy również zapewnić Państwu spersonalizowaną obsługę worków)

![]()

![]()

![]()