-

Maszyna do pakowania torebek

-

Maszyna do pakowania granulatu

-

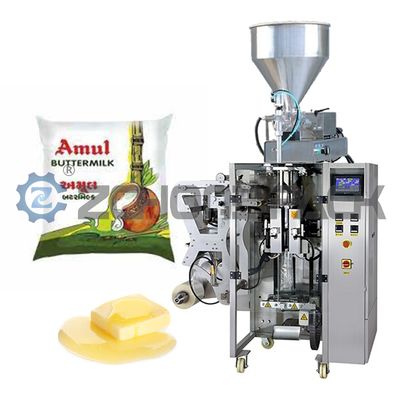

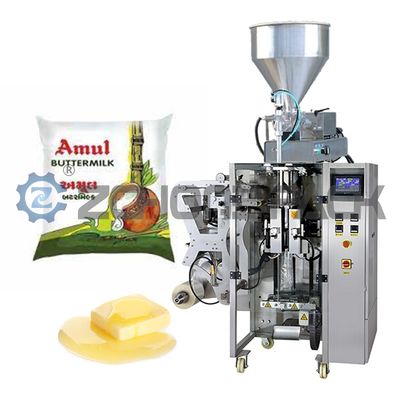

Maszyna do pakowania płynów

-

Maszyna do pakowania w proszku

-

Mini maszyna pakująca Doypack

-

Maszyna do pakowania torebek z herbatą

-

Maszyna do pakowania kawy

-

pionowa maszyna pakująca

-

Maszyna do pakowania przepływowego

-

Maszyna do pakowania w torebki stojące

-

Obrotowa maszyna do pakowania próżniowego

-

Maszyna do napełniania

-

Pozioma maszyna do pakowania Doypack

-

Gotowa torba

-

Akcesoria do maszyn pakujących

-

maszyny do wypełniania i pokrywania

Pionowa maszyna do pakowania z folii w rolce do żywności, zabawek i sprzętu

| Miejsce pochodzenia | Guangdong, Chiny |

|---|---|

| Nazwa handlowa | ZCHONE PACK |

| Orzecznictwo | ISO,CE |

| Numer modelu | ZC-200 |

| Minimalne zamówienie | 1set |

| Cena | $9,800~$28,900 |

| Szczegóły pakowania | Standardowe opakowanie drewniane export drewniane obudowy |

| Czas dostawy | 15 |

| Zasady płatności | L/C, D/A, D/P, T/T, Western Union, Moneygram |

| Możliwość Supply | 1/SETS/15DAD |

| Typ | Wielofunkcyjna maszyna pakująca | Nazwa produktu | Pakowarka Mini Doypack |

|---|---|---|---|

| Gwarancja | 1 rok | Serwis pogwarancyjny 1 | Wsparcie techniczne wideo |

| Serwis pogwarancyjny 2 | Wsparcie online | Serwis pogwarancyjny 3 | Części zapasowe |

| Podkreślić | pionowa maszyna pakująca z folii w rolce,Maszyna do tworzenia worków do pakowania żywności,pionowa maszyna do pakowania sprzętu |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

PionowaFwiedzaR/BagMAkingFOodToHArtykułyPakadowanieMszkodnik

1Co to jest pionowa maszyna do pakowania?

Maszyna opakowaniowa pionowa, znana również jako maszyna opakowaniowa typu "form, fill, and seal", jest wysoce zautomatyzowaną maszyną opakowaniową.Jego podstawową zasadą działania jest najpierw tworzenie torebek na miejscu z wykorzystaniem folii rolkowej (roll folii opakowaniowej).Następnie wypełnić worki produktem, a wreszcie uszczelnić i poderżnąć.

2. Kluczowe cechy

Wysoka wydajność: Automatyczne i ciągłe działanie umożliwia pakowanie kilkudziesięciu do setek toreb na minutę.

Oszczędności materiałów: Korzystanie z folii rolkowej obniża koszty materiałów i wymaga mniejszej powierzchni przechowywania niż torebki gotowe.

Wysoka elastyczność: Dzięki zastąpieniu różnych urządzeń pomiarowych i napełniających oraz podkładek może pakować różnorodne materiały, w tym granule, proszki, płynów, past i produkty masowe.

Opakowanie estetyczne: może wytwarzać różne rodzaje toreb, w tym torby z tylną uszczelnieniem, trzystronne uszczelnienie, czterostronne uszczelnienie i torby z gussetami,i może zintegrować dodatkowe funkcje, takie jak perforacja i łatwe wyrywki.

Niewielki odcisk: jego konstrukcja pionowa pozwala na kompaktową konstrukcję, oszczędzając miejsce w warsztacie.

3.Podstawowa zasada działania (proces trójstopniowy)

Przepływ pracy pionowej maszyny opakowaniowej można wyraźnie podzielić na trzy główne etapy:

I. Formowanie worków

Rola filmowa jest zamontowana na półce materiałowej z tyłu maszyny.

Film jest wyciągany, przechodzi przez urządzenie napięcia i rolki kierownicze i wchodzi do kluczowego elementu - pierwszego.

Pierwszy z nich zwalnia płaską folie w rurę, która jest "sercem" całej maszyny.

II. Wypełnianie

Utworzona rurka filmu przesuwa się w dół i przechodzi przez podłużne urządzenie uszczelniające, gdzie podłużny szwy filmu jest cieplnie uszczelniony, aby zakończyć rurkę.

Produkt wpuszczany jest do rurki workowej przez system pomiaru i napełniania znajdujący się na górze maszyny.System pomiarowy jest wybierany na podstawie właściwości materiału i może obejmować kubek pomiarowy, śrubę, wagę lub pompę ciekłą.

III. Pieczętowanie i cięcie

Po wypełnieniu poprzeczne urządzenie uszczelniające (parę głowic uszczelniających termicznie) działa jak para szynki, przyciskając rurę workową i uszczelniając ją termicznie jednocześnie na górze i na dole.

Górna pieczęć poprzeczna tworzy górną pieczęć bieżącego worka, podczas gdy dolna pieczęć poprzeczna tworzy dolną pieczęć następnego worka.

Następnie wewnętrzna lub zewnętrzna nożyca w środku przekrojowej uszczelnienia oddziela worki górne i dolne, umożliwiając wybicie worków gotowego produktu.

Proces ten powtarza się ciągle, osiągając ciągłe automatyczne pakowanie.

4Główne zastosowania

Maszyny opakowaniowe pionowe są szeroko stosowane, obejmując niemal wszystkie towary szybkiego przepływu (FMCG) zarówno w opakowaniach stałych, jak i ciekłych:

Przemysł spożywczy: przekąski, frytki, orzechy, cukierki, makaron, żywność dla zwierząt domowych, przyprawy, herbata, kawa, mrożone produkty itp.

Codzienny przemysł chemiczny: detergent do prania, szampon, próbki żelu prysznicowego, produkty do pielęgnacji skóry, chusteczki itd.

Przemysł farmaceutyczny: tabletki, kapsułki, plasterki z chińskich ziół i opatrunki.

Sprzęt i elektronika: śruby, orzechy i małe części.

Produkty chemiczne rolnicze: nasiona, nawozy i produkty chemiczne w małych dawkach.

Specyfikacja maszyny:

| Model | ZC-VP32 | ZC-VP42 | ZC-VP52 | ZC-VP62 |

| Prędkość pakowania | 10-50 worków/min | 10-50 worków/min | 10-50 worków/min | 5 ~ 50 worków/min |

| Wielkość worka | (L) 50- 190 mm (W) 50-150 mm | (L) 80-320 mm (W) 70- 200 mm | (L) 80-320 mm (W) 70- 200 mm | (L) 120-400 mm (W) 110-300 mm |

| Tworzenie torby | Tłuszcz z tylnym uszczelnieniem typu poduszkowy (folia rolkowa do materiału opakowaniowego, automatyczne wytwarzanie torebki maszynową jest uszczelnieniem górnym, dolnym i tylnym). | Worek poduszkowy (nieobowiązkowy: worek do stoczenia, worek z progiem, worek do uderzeń) | ||

| Maksymalna szerokość folii opakowaniowej | 320 mm | 420 mm | 420 mm | Maksymalnie 2500 ml |

| Zakres pomiaru | 500 ml | 1000 ml | 1000 ml | 620 mm |

| Grubość błony | 00,04 - 0,12 mm | 00,04 - 0,10 mm | 00,04 - 0,10 mm | 00,04 - 0,14 mm |

| Całkowity zestaw zużycia powietrza | 00,8Mpa 0,5m3/min | 00,8Mpa 0,3m3/分 | 00,8Mpa 0,3m3/分 | 00,8Mpa 0,5m3/min |

| Pojemność całkowita | 2.5KW/220V 50Hz | 2.7KW/220V 50Hz | 2.7KW/220V 50Hz | 4.2KW/220V 50Hz |

| Wymiary | (L) 1350* (W) 820* (H) 1150 mm | L1480*W960*H1400mm | L1480*W960*H1400mm | L1964*W1240*H1960mm |

| Waga przełącznika | 380 kg | 450 kg | 450 kg | 450 kg |

(Możemy zapewnić Państwu ekskluzywne usługi dostosowane do Państwa potrzeb!)

![]()

![]()

![]()

![]()

![]()